McCarthy Completes Neuroscience Research Building

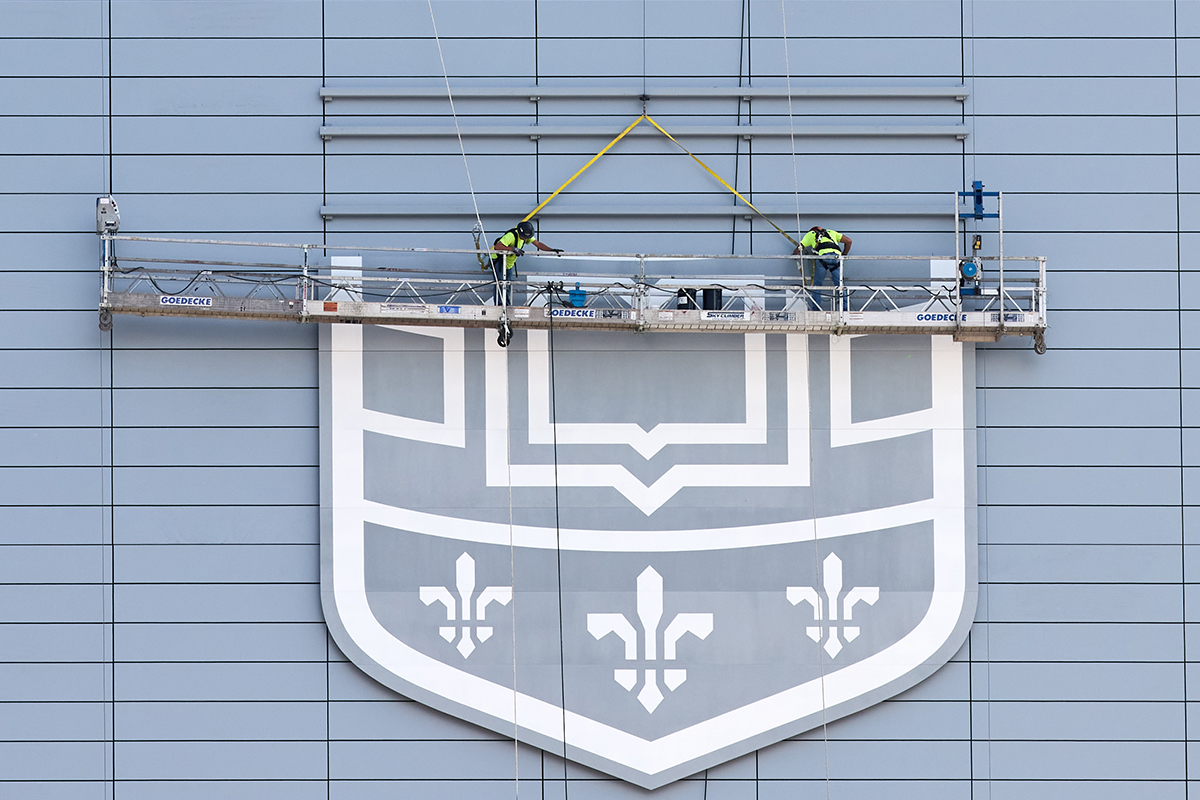

In August, McCarthy Building Companies completed Washington University School of Medicine’s Neuroscience Research Building in St. Louis’ Central West End.

The 11-story, 609,000-square-foot, $616 million facility, which broke ground in April 2020, was designed by Perkins+Will and CannonDesign. The project includes an 1,846-space parking garage and 2.5 floors of shell space.

The new Neuroscience Research Building brings together more than 100 research teams from across the university. Labs relocated from 11 building locations to the new facility and are now housed by research theme rather than by department as they’d long been. Primary areas of research performed within the new building are neuroscience, aging and brain science.

At prime occupancy, the NRB will house 1,300 full-time employees. Key areas on each building floor are designated for specific purposes to encourage collaboration.

A new utility plant and extended pedestrian walkway were also part of the construction scope. The two-story, 24,775-square-foot plant contains five 1,250-ton chillers, five cooling towers and two 3,000-kilowatt emergency power generators. Crews extended a 12-inch-high pressure steam line and five-inch condensate return line 2,400 feet underground from the Euclid Power Plant to the new NRB utility plant for the building’s steam utility needs.

The medical campus’ elevated link system was extended 1,000 feet through an existing parking garage, around an existing building and above Newstead Avenue. Drilled pier foundations surgically step around a spaghetti network of existing utilities which allows a 120-foot span above.

Takt planning – a lean construction scheduling tool that visually documents all work activities scheduled to take place every week throughout the project’s duration – greatly aided and expedited the enormous build. Efficiencies gained through Takt planning helped accelerate the installation of mechanical and electrical system components, which represented the largest scope of work in the research building.

About 90 percent of the M/E/P systems were prefabricated and pre-tested in several local prefab shops before they were delivered to the jobsite for installation. Detailed 3D modeling and early coordination enabled team members to understand the spatial constraints and generate fabrication drawings that they could follow in the shop.

Constructing essential components offsite in a controlled environment improved the quality and significantly reduced the number of onsite craft professionals required to install M/E/P components. This method also decreased the amount of waste generated at the jobsite.

The NRB facility is on track to achieve Leadership in Energy and Environmental Design Gold status.

Fresh Content

Direct to Your Inbox

YOUR CONSTRUCTION VOICE IN ST. LOUIS AND BEYOND

Join CNR Magazine today as a Content Partner

As a CNR Content Partner, CNR Magazine promises to support you as you build, design and engineer projects not only in and around St. Louis, but also across the U.S. CNR is equipped and ready to deliver a dynamic digital experience paired with the top-notch, robust print coverage for which you’ve always known and respected the magazine.